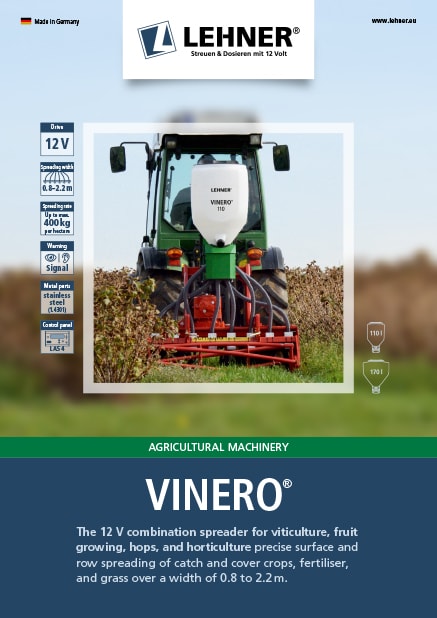

VINERO®

12 Volt hose spreader

The combination spreader for precise surface and row spreading of catch and cover crops, fertiliser, and grass!

With the VINERO® hose spreader, seeds of all types and granular fertiliser can be dispensed over a width of 0.8 – 2.2 m with extreme precision and flexibility – either in a separate work step or in combination with other working operations – surface spreading between the rows, or from the side directly into the rows with centimetre accuracy.

The VINERO® was specially developed for viticulture, fruit growing, hops, and horticulture, and can be installed on all vehicles with a 12 V supply. The discharge rate (max. 400 kg/ha) can be infinitely adjusted from the driver’s seat using the control panel, and can of course also be changed while on the move.

The advantages of the VINERO® are obvious:

- Infinitely adjustable working width from 0.8 – 2.2 m

- Transparent hopper with handy discharge opening

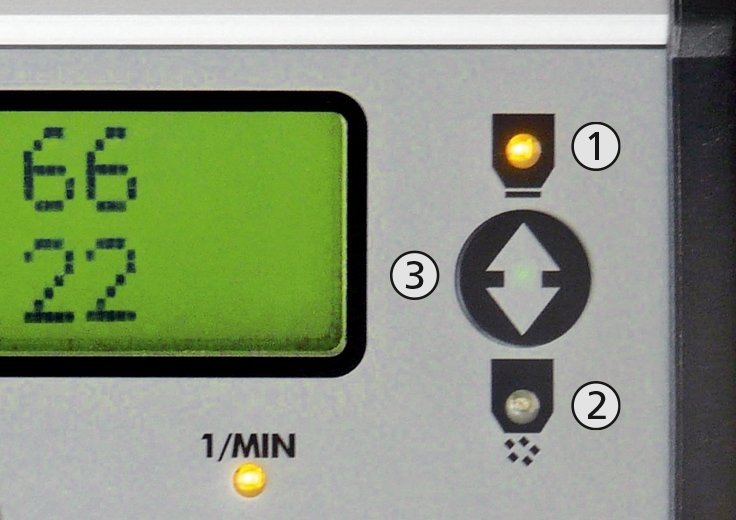

- Modern LAS 4 control panel with 2-line graphic display and visual and acoustic fault indication

- Infinite adjustment of the spreading dosage

- Frame, valve, agitator, and position-monitored valve of non-rusting stainless steel

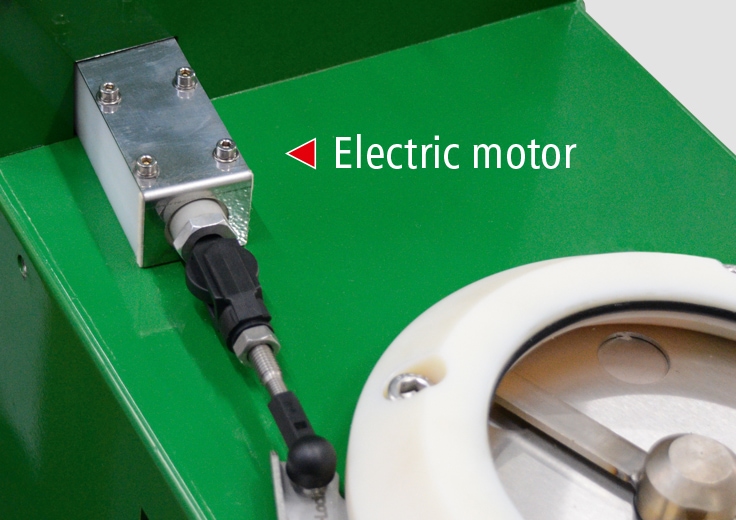

- Bladed agitator with separate 12 V drive

- 10 times autostart for agglomerated spreading material

- Water-resistant cables

- Readiness (socket) for headland management provided as standard

- Standard dosage plates: 4-hole (for self-installation) and 8-hole (pre-installed), LEHNER Superflex hose (10 m), battery cable (5 m) and control cable (6 m) as standard

- 4 or 8 hose outlets

Technical data

| Spreading width: | 0.8 – 2.2 m |

| Hose outlets: | 4 or 8 |

| Operating voltage: | 12 to 15 V |

| Motor power: | 120 W |

| Fuse: | 25 A |

| Speed range: | 40 – 66 rpm |

| Operating temperature: | -10 to +70 °C |

| Storage temperature: | -30 to +70 °C |

| Battery cable: | 5 m (2.5 mm²) |

| Control cable: | 6 m fixed connection to spreader, cable to control panel |

| Connections: | Power supply, control cable, headland management socket |

| Hopper capacity: | 110 l |

| Dimensions (LxWxH): | 485 x 570 x 1050 mm |

| Weight: | 31.5 kg |

| Hopper capacity: | 170 l |

| Dimensions (LxWxH): | 626 x 700 x 1070 mm |

| Weight: | 33 kg |

Special features of the VINERO®

As well as infinitely adjusting the discharge rate via the valve position and rotational speed, all other switching functions are also controlled directly via the control panel. These include Machine On/Off, Valve Open/Closed, checking the voltage, etc. In addition, the control panel issues a visual and acoustic warning (empty indicator) when the hopper level reaches the minimum, or the valve is not in position. Automatic valve control using a headland management system provides even more convenience.

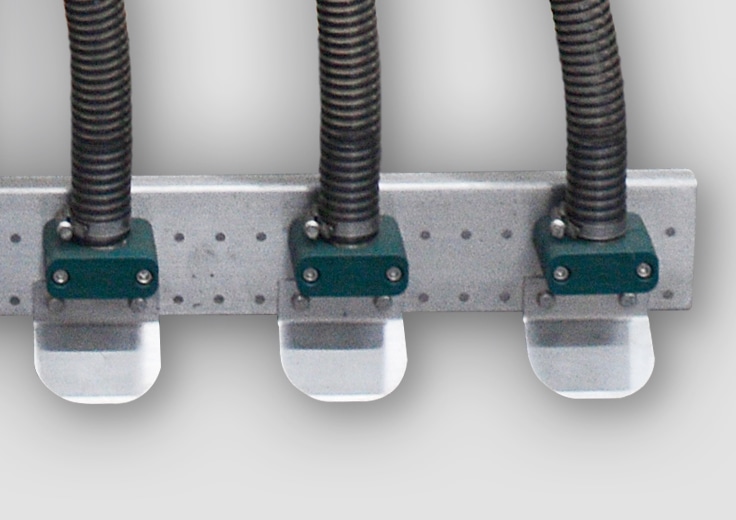

For spreading between the rows, all hoses are evenly spaced on the distributor rail. This accurately sets and limits the discharge width. The baffle plate under the hoses ensures optimum lateral distribution, and also minimises susceptibility to wind.

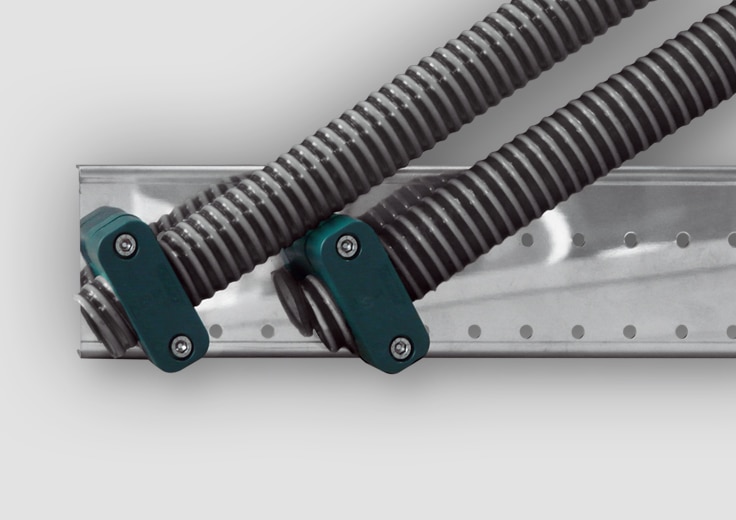

For fertilising in rows, the hoses on the rail are positioned inclined to the outside. The inner hoses can also be attached to the outside if necessary, thus increasing the discharge rate into the rows.

On the VINERO®, the flow rate of the spreading material is regulated directly on the control panel. In addition, the valve’s position is monitored to ensure an even discharge rate.

The valve unit can optionally and very easily be set for different outlet holes. For a narrow working width (80 cm), 4 holes are recommended; for a wide working width, 8 holes.

OPTIONAL: Headland manager (automatic valve control)

Downloads

Brochure

VINERO®

2 MB

Accessories

Relief roof for hopper

Battery cable with bracket (1x as standard)

Dosage slides

Brackets

Pick-up bracket, adjustable

Holding device for tailboard