VENTO® Duo

Pneumatic hose spreader with two-chamber system

Simultaneously spreading large legumes and small seed crops

The VENTO® Duo is a pneumatic 12-V hose spreader with two-chamber system, which was developed for simultaneously spreading two types of seed at different sowing locations or soil depths. For example, in a single operation, large legumes can be sown directly into the soil while small seed crops are dispensed at a different depth and location.

All functions and settings can be managed conveniently using the VENTO II control panel, and changed while you are on the move. Working widths from 1 – 6 m can be achieved, depending on the attached implement and hose routing.

VENTO® Duo – hits the target every time:

- 2 x 12 V high-powered fan and separately controlled rotary feeder shafts

- Both hopper sizes are available with a 50/50 or 65/35 split

- Control panel with 3.3 inch graphic display

- Speed-dependent dosing and headland management via 7-pin signal socket as standard

- Maximum hose length per outlet: 10 m

- Also included as standard: 16 baffle plates with U-brackets for mounting; 2 rotary feeder shafts (2x 5.0 ml, blue/outlet) plus rotary feeder set; LEHNER Superflex hose (50 m); 2 calibration bags and scale for calibration tests; Battery cable 6 mm2 (6 m); control cable (6 m); Transport and mounting frame

Technical data

| Spreading width: | 1 – 6 m |

| Hose outlets: | 16 |

| Fans: | 2 |

| Operating voltage: | 12.5 to 15 Volt |

| Speed range: | 20 – 120 rpm |

| Total power consumption: | max. 45 A |

| Motor power consumption: | 10 A |

| Operating temperature: | -10 to +50 °C |

| Storage temperature: | -10 to +50 °C |

| Battery cable: | 6 m (6.0 mm²) |

| Control cable: | 6 m Fixed connection to spreader Cable to control panel |

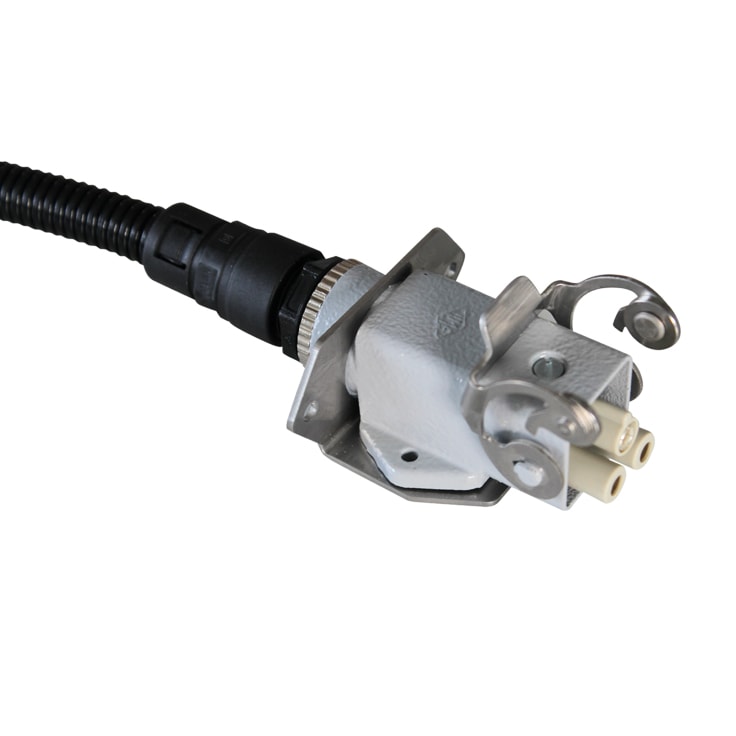

| Connections: | Power supply Control cable Headland management socket |

| Hopper capacity: | 230 l |

| Dimensions (LxWxH): | 947 x 570 x 1199 mm |

| Weight: | 84 kg |

| Hopper capacity: | 500 l |

| Dimensions (LxWxH): | 1155 x 755 x 1472 mm |

| Weight: | 186 kg |

Special features of the VENTO® Duo

On the VENTO II, all functions can be controlled centrally. Control of all features – whether speed-dependent dosing, electric calibration, or automated residue emptying – is completely user-friendly, simple and self-explanatory. Even the fan speed and rotary feeder shaft monitoring can be adjusted directly on the control panel. A choice of 18 languages and a program memory for up to 75 calibration tests make your work even more agreeable.

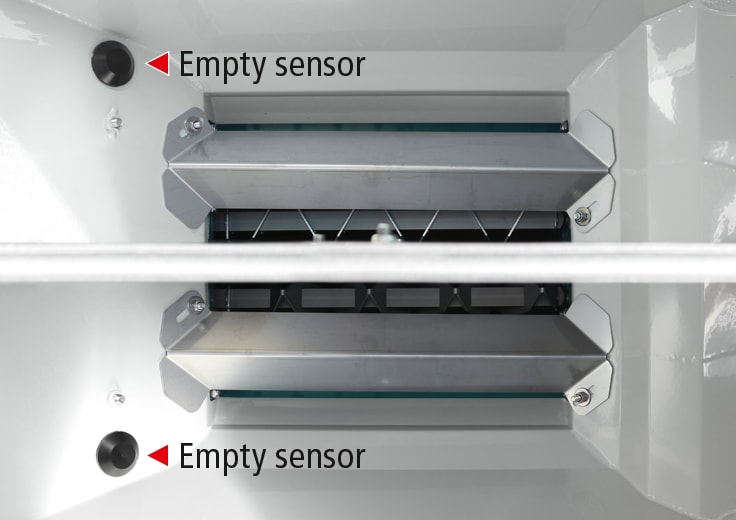

The hoppers of the VENTO® Duo are divided into two chambers (50/50 or 65/35 split). Each of the two chambers has its own empty indicator, agitator and load relief cover.

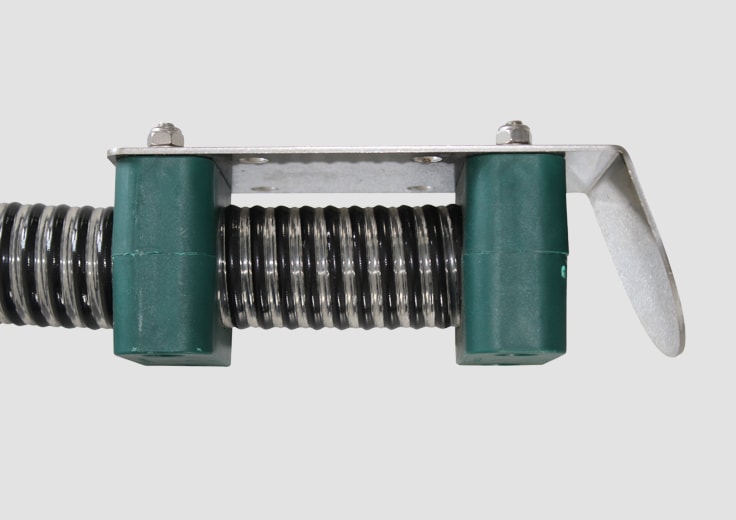

No tools are required to change rotary feeder shafts with various cells (A/B) for different spreading materials (fine, medium, large), or for attaching and detaching hoses.

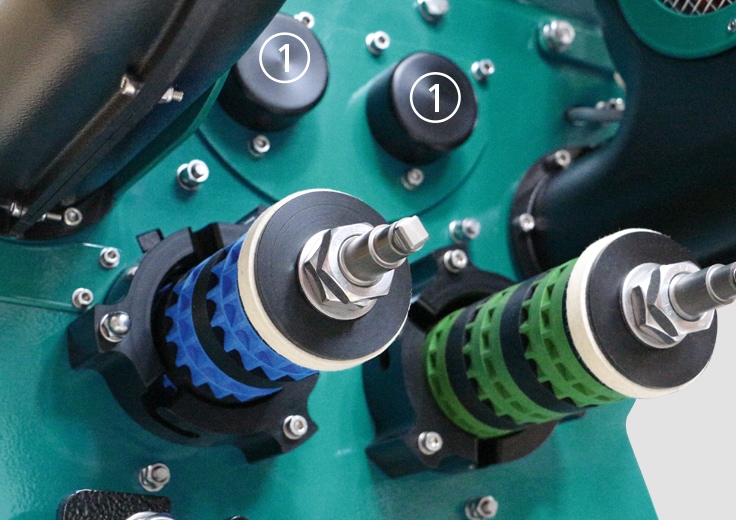

Using an optimum gear ratio, two separate agitators (1) in the hopper keep the feed running through uniformly and gently.

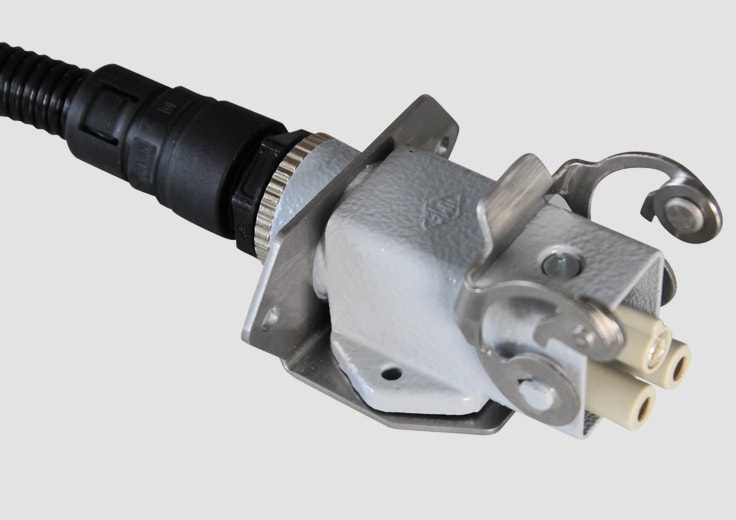

The VENTO® Duo is powered solely via the supplied 6 mm² battery cable. The battery cable is routed directly from the battery into the cab (holder included in delivery). The cable is protected by a plug-in fuse (40 A).

The VENTO® Duo comes with a blue rotary feeder shaft 2x 5.0 ml per outlet, and an additional set of star feeders. This comprises green 2.5 ml cells, red 10.0 ml cells, and dummy cells, so that mixtures of fine seeds and large legumes, small seed crops and micro granulate, can be dispensed.

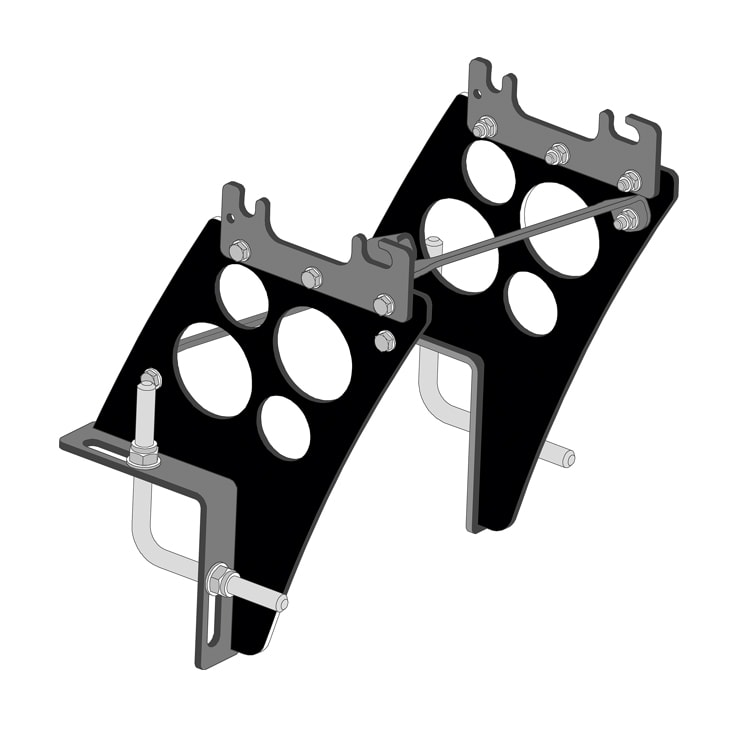

The VENTO® Duo comes as standard with 8 or 16 baffle plates with U-brackets. The baffle plate can therefore easilybe fixed to a square tube (40 x 40 mm). Square tube not included in delivery.

Downloads

Brochure

VENTO® Duo

3.2 MB

Accessories

VENTO battery cable

LEHNER Superflex hose set

Blind plug

Brackets

Universal mounting for square pipe