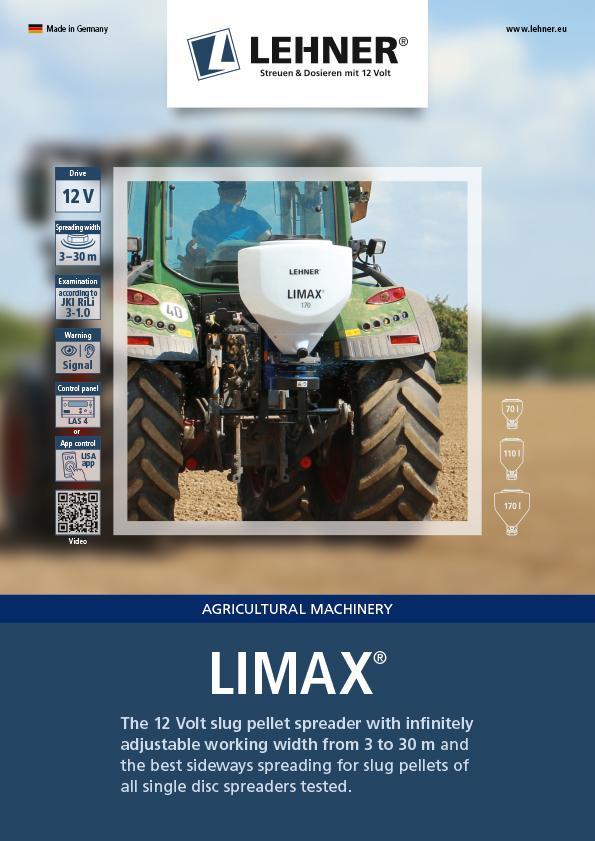

LIMAX®

12 Volt slug pellet spreader

The single disc spreader with the best transverse distribution for slug pellets up to 30 m in the test.

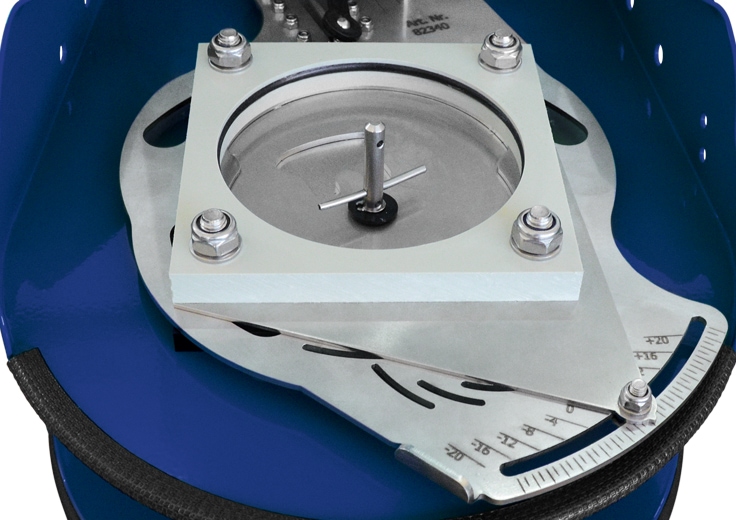

The LIMAX® was developed specifically to achieve an optimum, even spreading pattern when dispensing slug pellets at large working widths. This is made possible by a completely new development of the spreading disc, with both distributor blades, the valve unit, and the strike point adjustment.

The working width (3 to 30 m max.) is set from the comfort of the driver’s seat with the LAS4 control panel or the LISA app using the infinitely adjustable setting of the spreading disc speed. The material transfer via funnel directly in the middle of the spreading disc ensures an optimum strike point of the material on the spreading disc.

The LIMAX® sets the yardstick:

- Infinitely adjustable spreading width from 3 to 30 m

- Spreading disc with two long distributor blades with a total of 90 setting options and strike point adjustment (+/-20°) for spreading pattern optimisation

- Robust 12 V electric motor (300 W)

- Including LAS4 control panel as standard, e.g. for infinite adjustment of the spreading dosage, adjusting the spreading disc’s rotational speed and monitoring and controlling other switching functions – the LIMAX is also optionally available with app control in the 110 l and 170 l hopper sizes.

- Hopper with relief roof and discharge spout for convenient residue emptying

- Valve made of stainless steel

- 10-time autostart for agglomerated spreading material

- Readiness (socket) for headland management available as standard

- Tool-free hopper attachment/removal

Technical data

| Spreading width: | 3 – 30 m |

| Motor power: | 300 W |

| Speed range: | 200 – 3000 rpm |

| Fuse: | 25 A |

| Power consumption: | When starting, up to 24 A Normal operation up to 15 A |

| Operating voltage: | 12 to 15 V |

| Operating temperature: | -10 to +70 °C |

| Storage temperature: | -30 to +70 °C |

| Battery cable: | 5 m (4.0 mm²) |

| Control cable: | 6 m, fixed connection to spreader, cable to control panel |

| Connections: | Power supply, control cable, headland management socket |

| Hopper capacity: | 70 l |

| Controller: | LAS4 control panel |

| Dimensions (LxWxH): | 490 x 585 x 745 mm |

| Weight: | 22 kg |

| Hopper capacity: | 110 l |

| Controller: | LAS4 control panel |

| Dimensions (LxWxH): | 490 x 585 x 920 mm |

| Weight: | 31 kg |

| Hopper capacity: | 110 l |

| Controller: | LISA app |

| Dimensions (LxWxH): | 490 x 585 x 920 mm |

| Weight: | 31 kg |

| Hopper capacity: | 170 l |

| Controller: | LAS4 control panel |

| Dimensions (LxWxH): | 690 x 610 x 970 mm |

| Weight: | 33 kg |

| Hopper capacity: | 170 l |

| Controller: | LISA app |

| Dimensions (LxWxH): | 90 x 610 x 970 mm |

| Weight: | 33 kg |

Special features of the LIMAX®

Even spreading thanks to optimum transverse distribution

By means of the adjustable valve unit (+/-20°) and the 45 different settings for each distributor blade, the transverse distribution can be flexibly adjusted to the respective spread material, allowing for an even spreading pattern that previously only seemed possible with two-disc spreaders. In addition, valve geometry and low-friction valve guide ensure that even small quantities of spread material are finely dosed when spread, and the risk of the valve jamming is minimal.

The LAS 4 control panel of the LIMAX® incl. empty indicator

As well as exactly setting the working width by infinitely adjusting the rotational speed of the spreading disc, all other switching functions are also controlled directly from the control panel at the driver’s seat. These include On/Off, setting the adjustment valve for spreading dosage, checking the voltage, etc. What is more, the control panel issues a visual and acoustic warning when the hopper level is down to minimum or the valve is not in position.

App control instead of a control panel

You already use mobile apps for various applications/devices – don’t want to route any more cables in the driver’s cab, just get in/climb on and get started? Then the LEHNER spreaders with LISA control (LEHNER Intelligent Spreader App) are definitely the right choice instead of the conventional control unit. To operate the spreader, simply use your own mobile device with a holder (not included with the spreader) and the free LEHNER LISA app. Our LISA-compatible LEHNER spreaders are our own closed system solutions, which is why it is not possible to upgrade/retrofit existing LEHNER spreaders with a control panel to an app solution.

BEST SPREADING PATTERN IN THE TEST

During the test by the IRSTEA test institute, the LIMAX® came out on top for spreading results using slug pellets; up to now, this kind of quality had only been possible using a two-disc spreader.

At a working width of 30 m, the LIMAX® achieved a variation coefficient (C.V.) of 11.7%, and at 28 m a C.V. of 9.3% – the lower the C.V. value the more even the spreading pattern. For this, the distributor blades were positioned as follows: distributor blade 1: Hole 3/Point 1, distributor blade 2: Hole 3/Point 5, spreading disc speed: 2500 rpm.

Downloads

Brochure

LIMAX®

2 MB

Accessories

Battery cable with bracket (1x as standard)

Trolley

Cable connection (plug/socket)

Brackets

Pick-up bracket, adjustable

Holding device for tailboard