AgroDos®

12 V granulate spreader

The AgroDos® has the safest technology on the market for dispensing a great variety of granular materials during potato cultivation!

The spreading of pesticides such as Goldor Bait is permitted only using officially tested and certified spreaders which, like the AgroDos®, satisfy the most stringent safety criteria. With star feeder lock for extremely precise granulate dosing down to the milligram, and patented reversing when switching off or pulling out, any unwanted trickling out of product is reliably prevented. In addition, the AgroDos® starts up only on the move and with the hydraulics lowered. What’s more, the electronic lifting gear control is monitored to ensure that spreading stops automatically when pulling out, and the star feeder lock reverses 25°.

The AgroDos® leaves no wish unfulfilled:

- Certified by the German Federal Research Centre for Cultivated Plants (JKI) since February 2010

- Operation with 12 V electric motor

- Choice of hopper volume 12, 22, or 70 l

- Electric calibration and complete emptying as standard

- Control panel with 2-line graphic display for easy change of pesticide application rate and row spacing

- Application rate adjustment +/- 20%

- The spreader is easy to attach and couple to the planter (electric or mechanical coupling)

- Manual or route-dependent operation possible

- Rotary feeder shaft with M cells

- Also included in delivery: 2x fishtail distributors, 5m spiral 20 mm PVC hose, battery cable (5 m), control cable (4 m) and headland management cable (2.4 m)

- Device control according to JKI RiLi 3-1.0 incl. test seal and test report

Fields

Spreading pesticides

on potato plants, using the AgroDos®

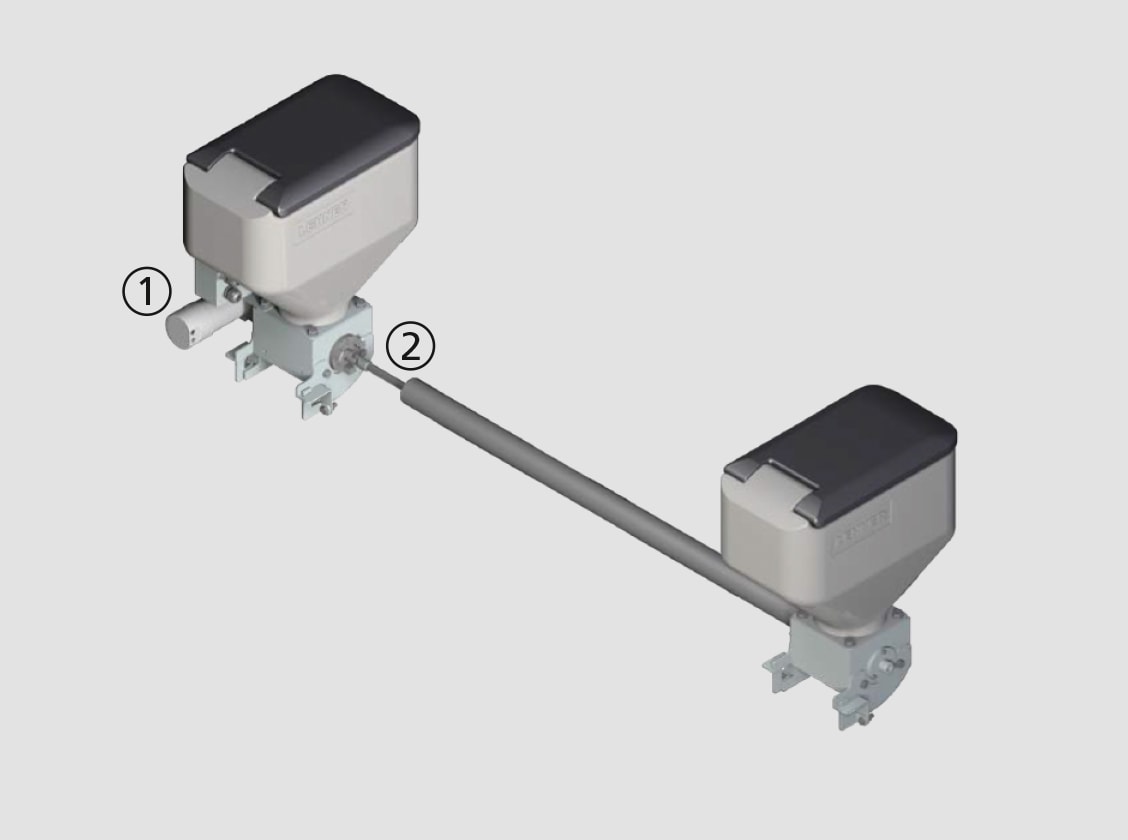

AgroDos® connected mechanically

e.g. on a 4-row potato planting machine

Electrical connection

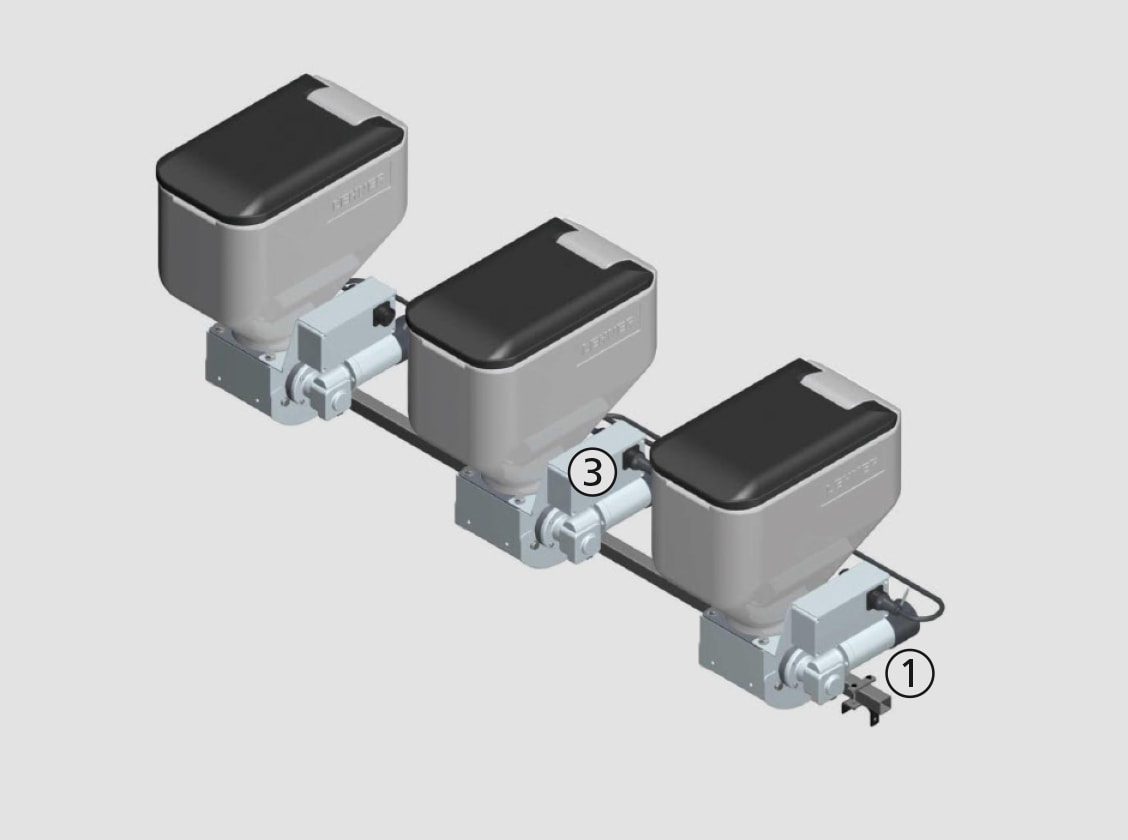

6 AgroDos® on an 18-row beet sowing appliance

Technical data

| Operating voltage: : | 12 to 15 V |

| Fuse: | 25 A |

| Power consumption: | 3 A |

| Speed range: | 20 – 120 rpm |

| Operating temperature: | -10 to +70 °C |

| Storage temperature: | -30 to +70 °C |

| Battery cable: | 5 m (4.0 mm²) |

| Control cable: | 4 m, fixed connection to spreader, cable to control panel |

| Connections: | Power supply, control cable, headland management socket |

| Hopper capacity: | 12 l |

| Dimensions (LxWxH): | 250 x 462 x 480 mm |

| Weight: | 10 kg |

| Drive: | Straight drive |

| Hopper capacity: | 22 l |

| Dimensions (LxWxH): | 300 x 425 x 535 mm |

| Weight: | 11 kg |

| Drive: | Angled drive |

| Hopper capacity: | 70 l |

| Dimensions (LxWxH): | 489 x 554 x 788 mm |

| Weight: | 22 kg |

| Drive: | Angled drive |

Special features of the AgroDos®

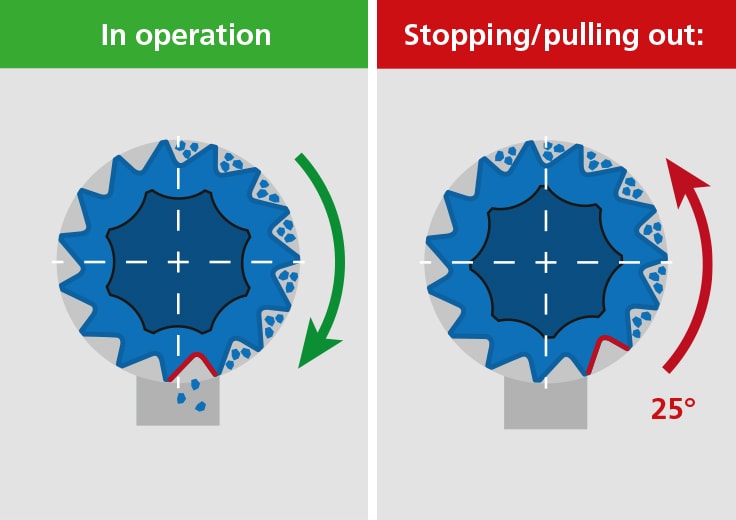

Reversing star feeder lock prevents additional material trickling out

The AgroDos® is equipped with patented auto-reverse from LEHNER; this reverses the star feeder lock 25° when the machine is stopped. This reliably prevents even the tiniest quantity of granulate from exiting when unintendedly. Should you ever forget to stop “manually”, the electronic lifting gear control monitor transmits a signal to switch off when pulling out. Moreover, the AgroDos® is configured to ensure that it can start up when only on the move and with the hydraulics lowered.

LAS 4 PSM control panel for safe and reliable control of the AgroDos®

As well as setting the dosage by adjusting the speed of the star feeder lock, all other switching functions are also controlled via the control panel, e.g. On/Off, start/stop, setting the electronic lifting gear control signal, automated residue emptying, electric calibration and setting up of your own products (spreading charts). A choice of five languages and a program memory for up to 12 calibration tests rationalise your work even more. Speed-dependent dosing via a 7-pin signal socket or wheel speed sensor is also possible (accessories).

TYPE OF COUPLING:

Electric version

With the electric coupling, all spreaders are equipped with a gear motor (1). To add a spreader, simply plug its cable into the multi-pin socket (3) of the spreader that’s already attached – and you’re ready to go! This very simple coupling is therefore used more frequently than the mechanical version.

Mechanical version

With a mechanical coupling, only the first spreader has a gear motor (1) installed; this drives the additional spreaders via a cardan shaft (2). However, when attaching the AgroDos®spreader to the planter, you must make sure that all granulate spreaders are parallel with one another.

Downloads

Brochure

AgroDos®

2 MB

Accessories

Retrofit Mocap lid

Battery cable with bracket (1x as standard)