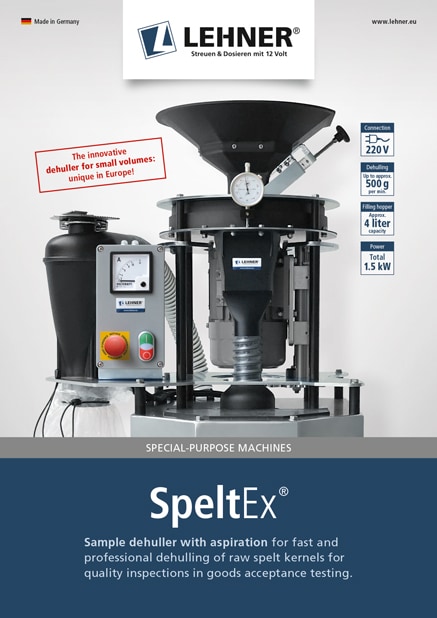

SpeltEx®

Sample dehuller with aspiration

Dehull spelt kernel samples in the blink of an eye

With the SpeltEx®, delays in receiving goods due to time-consuming, makeshift dehulling processes for small volumes are now a thing of the past. The SpeltEx® is extremely fast and thorough. In just one minute, the SpeltEx® delivers approx. 500 g of perfectly dehulled spelt for subsequent tests of the falling number, DON, protein and water. What is more, this dehulling process, with adjustable dehuller discs and aspiration, is exactly reproducible and gentle on the grains.

SpeltEx®

3,01 MB

Technical Data

General features of the sample dehuller SpeltEx®

- Simply, user-friendly operation Precise display of all dehulling setting parameters for reproducible results

- durable, robust and highly effective technology

- Easy-clean, high-quality materials

- High empty weight and five vibration dampers (feet) for optimum stability

- Max. volume in working operation: approx. 94 dB(A)

- Two reinforced hull bags supplied

- Optional accessories: Spelt valve, Cooler (only standard with the SpeltEx® Pro)

- Capacity: approx. 4 l

- Supply voltage: 220 V

- Total power consumption: 1,500 W

SpeltEx® Pro – ideal for large acceptance testing stations and shift operation

With threshed raw kernels, in particular, the SpeltEx® Pro demonstrates its superiority. What is more, it is very easy to operate. The SpeltEx® Pro can also process spelt glumes with two or three spikelets without causing a blockage. Once it has been set, it delivers one electronically monitored raw spelt sample after another – in constantly high dehulled quality. This hugely increases throughput during goods acceptance testing, especially at peak times. Also, testing capacity is utilised to the max without the need to allocate staff specifically for monitoring or checking the dehulling process.

Further features of the SpeltEx® Pro:

- Constant supply of raw kernels without manual intervention

- Precisely control the raw kernel flow rate on the control panel

- Electronic monitoring protects the dehuller drive from overload

- Easy access to all main components

- Cooler included as standard

| Designation: | SpeltEx® |

| Dimensions (LxWxH): | 605 x 520 x 980 mm |

| Weight: | approx. 82 kg |

| Designation: | SpeltEx® Pro |

| Dimensions (LxWxH): | 605 x 520 x 1.080 mm |

| Weight: | approx. 90 kg |

Controls of the SpeltEx®

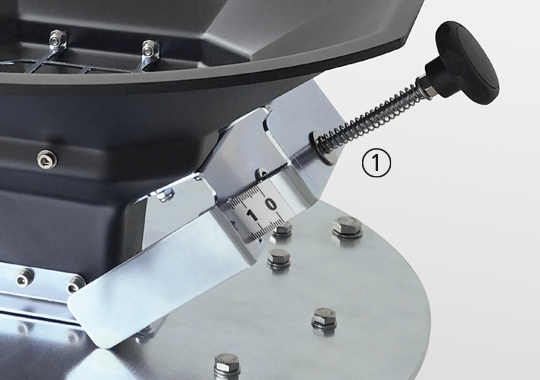

The dosage quantity and loosening of the grains are controlled by a spring-mounted dosing valve (1).

Throttle valve (2) on the cyclone for setting the aspiration rate (16 positions).

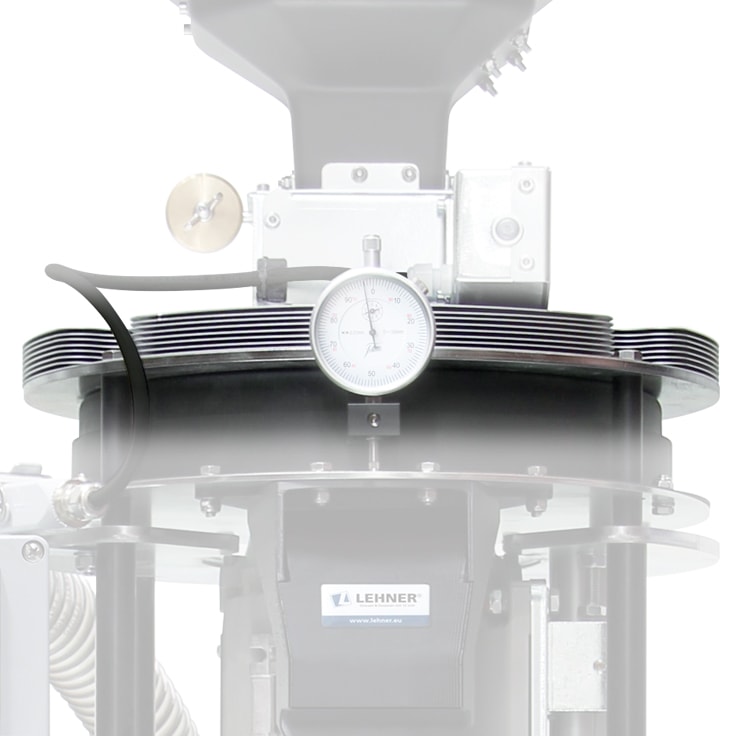

Adjustment wheel (3) for setting the dehulling gap.

Control unit with On/Off, Emergency Stop and ammeter for the dehuller motor to monitor electricity consumption (nominal value: 4–6 A).

Special features of the SpeltEx® Pro

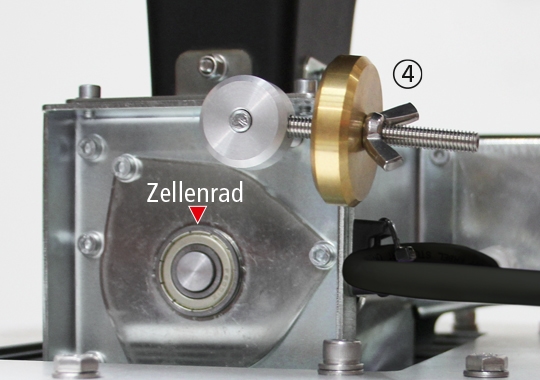

Baffle plate weight (4) for rough adjustment of the constant raw material feed rate. Fine adjustment is made by controlling the cellular wheel shaft on the control panel.

Stepless fine adjustment of the dosing quantity using the speed of the cellular wheel shaft. The load of the desmelter drive is electronically monitored and the speed is adjusted if necessary to prevent overload or overdosing.

Accessories

Spelt valve