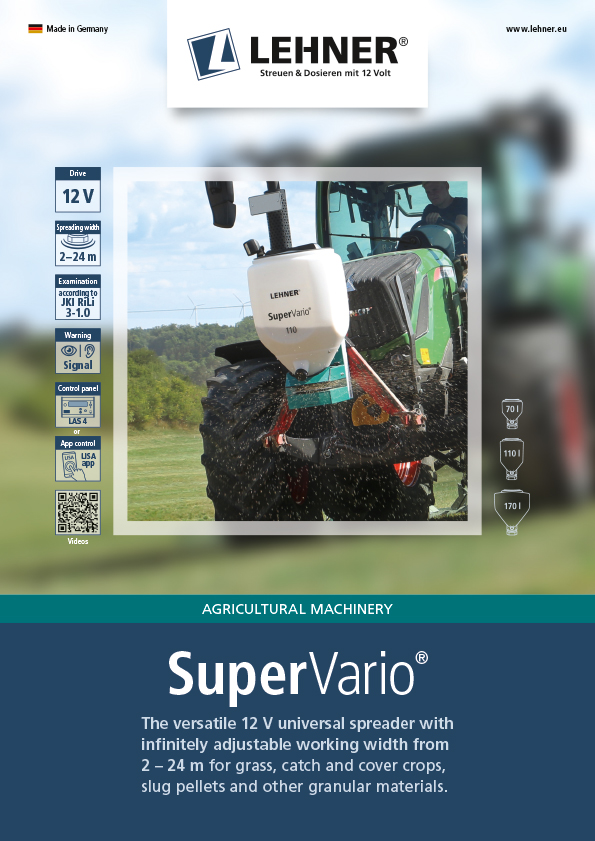

SuperVario®

The 12 V universal spreader

Grasses, cover crops, slug pellets and other granules should be perfectly dosed and sprinkled.

The SuperVario® from LEHNER is a universal spreader for use in agriculture, with a 12 V drive for operation independent of other drives, such as the cardan shaft or hydraulics. This way, two work operations can frequently be combined into one, achieving long-term savings in cost and time.

The working width can be flexibly adjusted from 2–24 m by infinitely adjusting the speed of the SuperVario® spreading disc between 200 and 3,000 rpm – from the comfort of the cab via the standard LAS4 control panel or app control. In addition, both control systems have various monitoring functions, such as empty indicator, automatic valve monitoring, etc.

The SuperVario® offers, including:

- Robust 12 V electric motor (300 W)

- Hopper with relief roof and discharge spout for convenient and thorough residue emptying

- Valve and spreading disc of non-rusting stainless steel

- Including control panel with 2-line graphic display as standard (optionally with AUTO-DOSIS), or instead of this for the SuperVario® 110 LISA and SuperVario® 170 LISA with app control and speed-dependent dosing.

- Visual and acoustic fault indication on the control panel

- 10-time autostart for agglomerated spreading material

- Infinitely adjustable distributor blades for adjusting the spreading pattern – sideways spreading

- Readiness (socket) for headland management available as standard

- Tool-free hopper attachment/removal

- Water-tight junction box

- Device control according to JKI RiLi 3-1.0 incl. test seal and test report

Fields

Reseeding grassland

when harrowing grass areas

Sowing of cover crops

eg. one-sided when ploughing

Spreading slug pellets

for example when sowing the main crop

Technical data

| Spreading width: | 2 – 24 m |

| Motor power: | 300 W |

| Speed range: | 200 – 3000 rpm |

| Fuse: | 25 A |

| Power consumption: | When starting, up to 24 A Normal operation up to 15 A |

| Operating voltage: | 12 to 15 V |

| Operating temperature: | -10 to +70 °C |

| Storage temperature: | -30 to +70 °C |

| Battery cable: | 5 m (4.0 mm²) |

| Control cable: | 6 m, fixed connection to spreader, cable to control panel |

| Connections: | Power supply, control cable, headland management socket |

| Hopper capacity: | 70 l |

| Controller: | LAS4 control panel |

| Dimensions (LxWxH): | 490 x 585 x 745 mm |

| Weight: | 22 kg |

| Hopper capacity: | 110 l |

| Controller: | LAS4 control panel |

| Dimensions (LxWxH): | 490 x 585 x 920 mm |

| Weight: | 31 kg |

| Hopper capacity: | 110 l |

| Controller: | LISA app |

| Dimensions (LxWxH): | 490 x 585 x 920 mm |

| Weight: | 31 kg |

| Hopper capacity: | 170 l |

| Controller: | LAS4 control panel |

| Dimensions (LxWxH): | 690 x 610 x 970 mm |

| Weight: | 33 kg |

| Hopper capacity: | 170 l |

| Controller: | LISA app |

| Dimensions (LxWxH): | 690 x 610 x 970 mm |

| Weight: | 33 kg |

Special features of the SuperVario®

Spreading with comfort and convenience – the LAS 4 control panel with empty indicator:

As well as setting the working width by infinitely adjusting the rotational speed of the spreading disc, all other switching functions are also controlled via the control panel. These include On/Off, setting the adjustment valve for spreading dosage, checking the voltage, etc.

What’s more, the control panel issues a visual and acoustic warning when the hopper level is down to minimum or the valve is not in position. Enjoy even greater convenience with speed-dependent dosage via the AUTO-DOSIS control unit.

App control instead of a control panel

You already use mobile apps for various applications/devices – don’t want to route any more cables in the driver’s cab, just get in/climb on and get started? Then the LEHNER spreaders with LISA control (LEHNER Intelligent Spreader App) are definitely the right choice instead of the conventional control unit. To operate the spreader, simply use your own mobile device with a holder (not included with the spreader) and the free LEHNER LISA app. Our LISA-compatible LEHNER spreaders are our own closed system solutions, which is why it is not possible to upgrade/retrofit existing LEHNER spreaders with a control panel to an app solution.

The vital difference

The valve and spreading disc are made of non-rusting stainless steel (stainless steel frame available at additional cost). The agitator can be equipped with an agitator finger (included) especially for sowing grass seed.

Flexible & sturdy in the field

With its 12 V technology and extensive range of attachments, the SuperVario® can be installed on virtually any agricultural vehicle, e.g. ATV, pickup, etc.

OPTIONAL: AUTO-DOSIS

AUTO-DOSIS automatically adjusts the valve position in line with the driving speed.

After you have selected the material, entered the desired spreading width and discharge rate per hectare, the AUTO-DOSIS automatically reacts to braking and acceleration manoeuvres and controls the dosing valve, keeping the discharge rate kg/ha constant.

1. AUTO-DOSIS via 7-pin signal socket

Here, the travel speed is recorded via the 7-pin signal socket on the tractor. In this version, the signal socket also provides the headland management system.

2. AUTO-DOSIS via GPS receiver

The speed is determined by GPS and forwarded to the control panel.

Downloads

Brochure

SuperVario®

2 MB

Accessories

Deflector plate for “ploughing on the right”

Battery cable with bracket (1x as standard)

Stainless steel construction for 110 and 170 version

Brackets

Pick-up bracket, standard

ATV/quad bracket “at the top”