Download-Center

Online catalogue

3D view

Partners worldwide

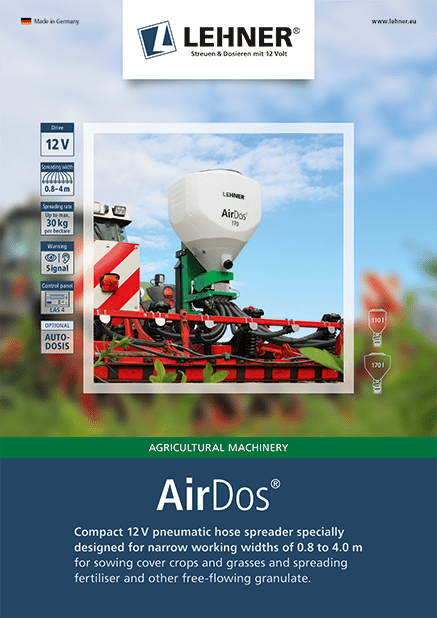

AirDos®

Pneumatic hose spreader for narrow working widths

With working widths of up to 4 metres, it’s hard to beat

The AirDos® pneumatic hose spreader can be easily and quickly mounted on a variety of tillage implements, so that spreading can be combined with another work process to save time. With its infinitely adjustable fan, mixtures of fine and large seeds, fertiliser, micro granules and grasses can be dosed with precision (max. 30 kg/ha) and dispensed over a width of 0.8 to 4 m.

Control all the functions required for this in the cab while driving, using the supplied LAS4 control panel. But that’s not all: The AirDos® also delivers excellent value for money, quality, handling and performance.

The advantages of the AirDos® are many and diverse:

- The rotary feeder shaft and fan are powered separately by their own 12 V motors

- Transparent hoppers (2 sizes) with residue discharge

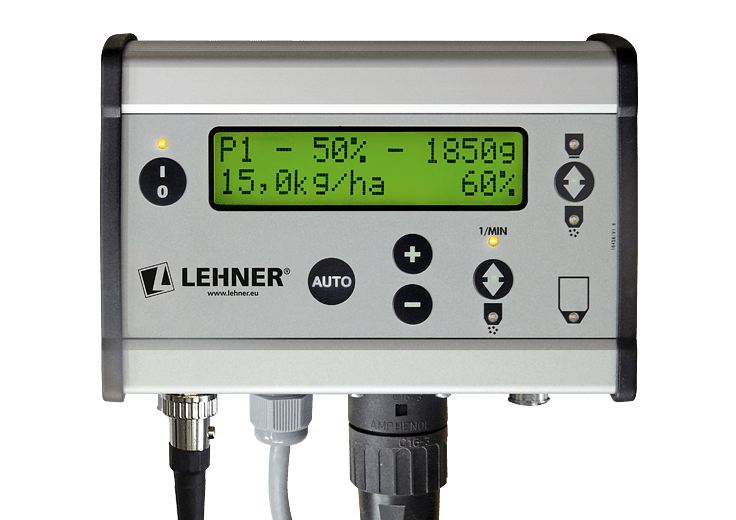

- Control panel with 2-line graphic display as standard and AUTO-DOSIS as an optional accessory

- Visual and acoustic fault indication on the control panel

- Infinitely adjustable fan speed from 0 to 100%

- Infinite adjustment of the spreading dosage

- Socket for headland management provided as standard

- Supplied as standard with: 25 m Superflex hose, 8 baffle plates with fastening material, 6 m control cable, rotary feeder shaft (1x 5.0 ml blue/outlet) plus a rotary feeder set containing green 2.5 ml cells and red 10.0 ml cells

Technical Data

| Spreading width: | 0.8 – 4 m |

| Hose outlets: | 8 |

| Fan: | 1 |

| Operating voltage: | 12.5 to 15 Volt |

| Speed range: | stepless, 0 – 100 % rotary feeder shaft, fan motor |

| Engine power: | Starting: up to 600 W, Normal operation: 50 W |

| Fuse: | 25 A |

| Operating temperature: | -10 to +70 °C |

| Storage temperature: | -30 to +70 °C |

| Battery cable: | Not included in the delivery |

| Control cable: | 6 m, fixed connection to spreader, cable to control panel |

| Connections: | Power supply, control cable, headland management socket |

| Hopper capacity: | 110 l |

| Dimensions (LxWxH): | 496 x 582 x 1,130 mm |

| Weight: | 35 kg |

| Hopper capacity: | 170 l |

| Dimensions (LxWxH): | 622 x 697 x 1,166 mm |

| Weight: | 38 kg |

Special features of the AirDos®

Simple, convenient control from the driver’s seat – LAS 4 control panel:

As well as infinitely adjusting the discharge rate via the speed of the rotary feeder shaft and fan, all other switching functions are also controlled directly via the control panel. These include machine On/Off, checking the voltage, electrical calibration, etc.

In addition, the control panel issues visual and acoustic warnings in the event of malfunctions and if the motor is not at the required speed. Enjoy even greater convenience with speed-dependent dosing via AUTO-DOSIS.

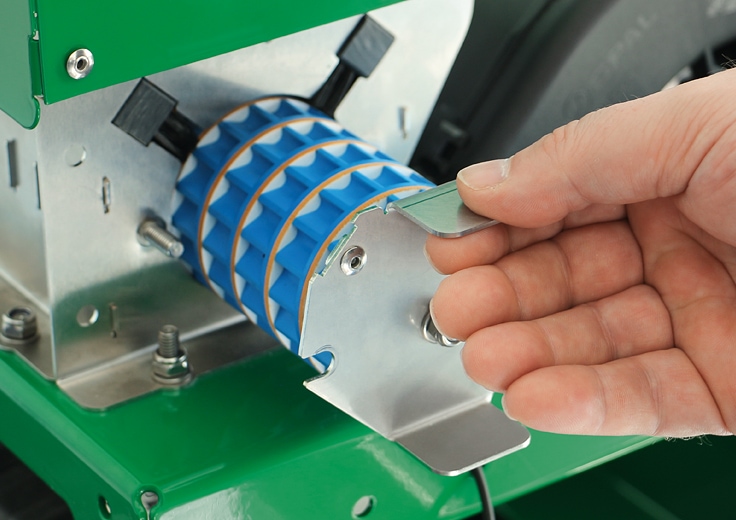

Removing the rotary feeder shaft

To change the rotary feeder shaft with different cells (red, green, blue) for different spreading materials, simply undo the two locking screws – no tools needed.

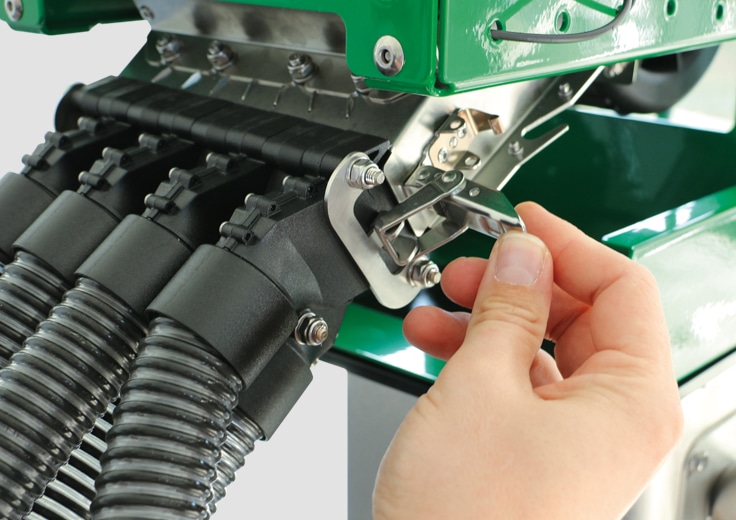

Removing/fitting the hose unit

In the AirDos®, the 8 outlets are arranged in two rows one behind the other, forming a very compact unit. This means that for removal, you simply undo the hinge on the side, and the entire unit can be decoupled from the spreader (e.g. for a calibration test).

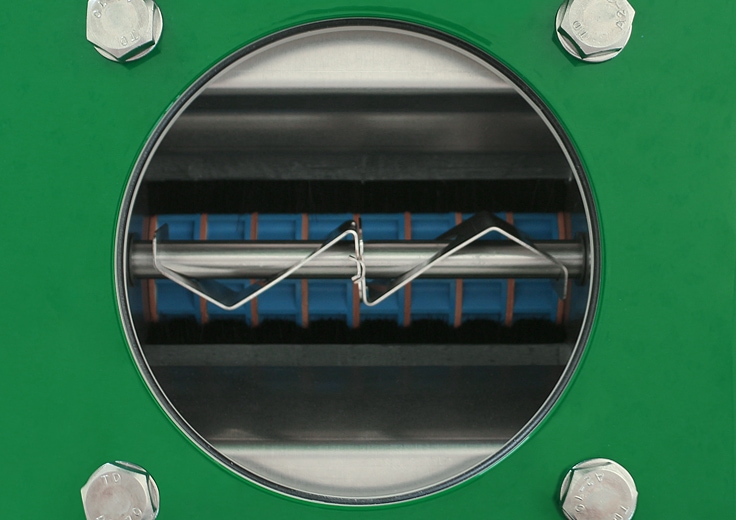

Stainless steel agitator

The stainless steel agitator above the rotary feeder shaft breaks up the material and ensures a homogeneous flow. The agitator is easy to access and clean when needed.

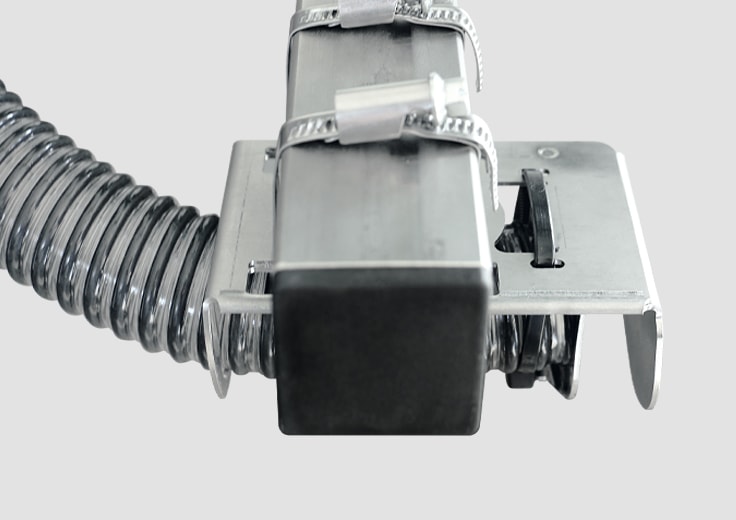

Baffle plates

The baffle plates are manufactured and moulded from a single piece. They are exceptionally stable and can effortlessly be secured anywhere. The fastening material is included in the scope of delivery – but the pictured square tube is not.

OPTIONAL: AUTO-DOSIS

Speed-dependent dosing for additional ease of use

AUTO-DOSIS automatically adjusts the valve position in line with the driving speed. After you have selected the material and entered the desired spreading width and rate per hectare, AUTO-DOSIS automatically reacts to braking and acceleration manoeuvres and controls the dosing valve accordingly. This keeps the desired spreading rate constant.

1. AUTO-DOSIS via 7-pin signal socket

Here, the travel speed is recorded via the 7-pin signal socket on the tractor. In this version, the signal socket also provides the headland management system.

2. AUTO-DOSIS via GPS receiver

The speed is determined by GPS and forwarded to the control panel.

Downloads

Brochure

AirDos®

2 MB

Accessories

Calibration bag

AirDos blind plug

Battery cable with bracket

Brackets

Cultivator bracket, standard

Cultivator bracket for triangular