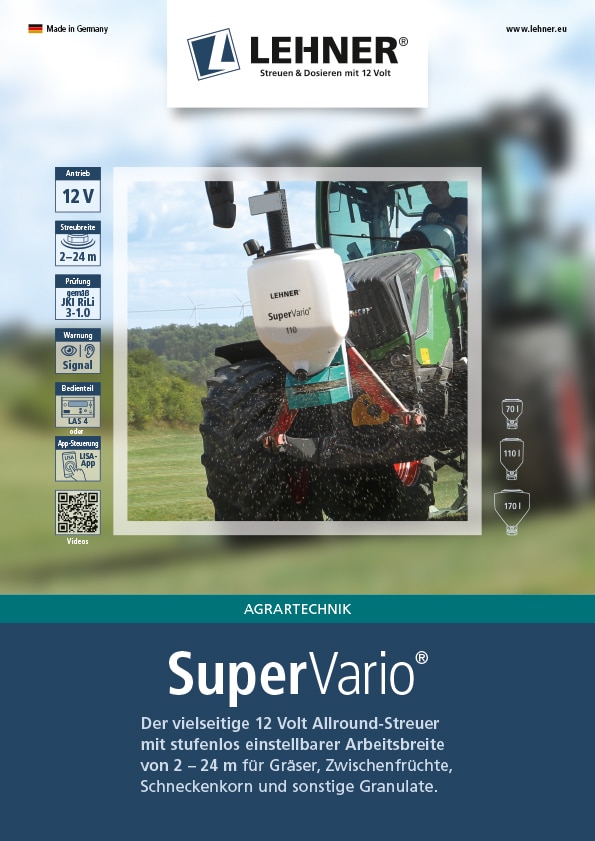

SuperVario®

Der 12 Volt Allround-Streuer

Gräser, Zwischenfrüchte, Schneckenkorn und sonstige Granulate perfekt dosieren und gezielt streuen.

Der SuperVario® ist ein Universal-Streuer für die Landwirtschaft, der durch seinen 12 V-Antrieb unabhängig von anderen Antrieben, wie Kardan oder Hydraulik, betrieben wird. Somit lassen sich häufig zwei Arbeitsgänge zeitsparend zu einem zusammenfassen, wodurch sich Aufwand und Kosten nachhaltig reduzieren.

Die Arbeitsbreite ist flexibel zwischen 2 – 24 m einstellbar, da sich der Streuteller des SuperVario® stufenlos zwischen 200 und 3.000 U/min regulieren lässt – bequem von der Fahrerkabine aus via serienmäßigem LAS4-Bedienteil oder App-Steuerung. Zudem verfügen beide Steuerungen über diverse Überwachungsfunktionen wie Leermelder, automatische Schieberüberwachung etc.

Der SuperVario® bietet, u.a.:

- Robuster 12 V-Elektromotor (300 Watt)

- Behälter mit Entlastungsdach und Auslaufstutzen zur komfortablen Restentleerung

- Schieber und Streuteller aus rostfreiem Edelstahl

- Serienmäßig inkl. Bedienteil mit 2-zeiligem Grafikdisplay (optional mit AUTO-DOSIS) oder anstelle dieser beim SuperVario® 110 LISA und SuperVario® 170 LISA mit App-Steuerung und geschwindigkeitsabhängiger Dosierung

- Optische und akustische Fehlermeldung am Bedienteil

- 10-malige Startautomatik bei festgerütteltem Streugut

- Stufenlos verstellbare Wurfschaufeln zum Einstellen des Streubildes

- Vorbereitung für das Vorgewende-Management serienmäßig vorhanden

- Werkzeuglose Behältermontage bzw. -demontage

- Wasserdichter Verteilerkasten

- Gerätekontrolle nach JKI RiLi 3-1.0 inklusive Prüfsiegel und Prüfbericht

Einsatzgebiete

Grünland-Übersaat

beim Abeggen von Grasflächen

Zwischenfrucht streuen

z. B. einseitig beim Pflügen

Schneckenkorn ausbringen

beispielsweise mit der Hauptkultur

Technische Daten

| Streubreite: | 2 – 24 m |

| Motorleistung: | 300 Watt |

| Drehzahlbereich: | 200 – 3.000 U/min |

| Sicherung: | 25 A |

| Stromaufnahme: | Start bis 24 A Normalbetrieb bis 15 A |

| Betriebsspannung: | 12 bis 15 Volt |

| Betriebstemperatur: | -10 bis +70 °C |

| Lagertemperatur: | -30 bis +70 °C |

| Batteriekabel: | 5 m (4,0 mm²) |

| Steuerkabel: | 6 m, Festanschluss am Streuer, Kabel zum Bedienteil |

| Anschlüsse: | Stromversorgung, Steuerkabel, Vorbereitung VGM-Dose |

| Behälterinhalt: | 70 l |

| Steuerung: | LAS4-Bedienteil |

| Maße (LxBxH): | 490 x 585 x 745 mm |

| Gewicht: | 22 kg |

| Behälterinhalt: | 110 l |

| Steuerung: | LAS4-Bedienteil |

| Maße (LxBxH): | 490 x 585 x 920 mm |

| Gewicht: | 31 kg |

| Behälterinhalt: | 110 l |

| Steuerung: | LISA-App |

| Maße (LxBxH): | 490 x 585 x 920 mm |

| Gewicht: | 31 kg |

| Behälterinhalt: | 170 l |

| Steuerung: | LAS4-Bedienteil |

| Maße (LxBxH): | 690 x 610 x 970 mm |

| Gewicht: | 33 kg |

| Behälterinhalt: | 170 l |

| Steuerung: | LISA-App |

| Maße (LxBxH): | 690 x 610 x 970 mm |

| Gewicht: | 33 kg |

Besonderheiten des SuperVario®

Bequem und komfortabel streuen – das Bedienteil LAS 4 mit Leermelder:

Neben der Einstellung der Arbeitsbreite mithilfe der stufenlosen Drehzahleinstellung des Streutellers, lassen sich auch alle weiteren Schaltfunktionen am Bedienteil vornehmen z.B. Ein-/Aus, Schiebereinstellung zur Streumengen-Dosierung, Spannung prüfen etc.

Das Bedienteil warnt zudem optisch und akustisch beim Erreichen der Mindestmenge im Behälter bzw. Abweichung der Drehzahl sowie Nicht-Erreichen der Schieberposition. Noch mehr Komfort bietet die geschwindigkeitsabhängige Dosierung via AUTO-DOSIS Steuerung.

App-Steuerung anstelle eines Bedienteils

Sie nutzen für diverse Anwendungen/ Geräte bereits mobile Applikationen – wollen keine Kabel mehr in die Fahrerkabine verlegen, einfach ein-/aufsteigen und loslegen? Dann sind die LEHNER-Streuer mit LISA-Steuerung anstelle des klassischen Bedienteils bestimmt die richtige Wahl. Zur Streuer-Bedienung nutzen Sie einfach Ihr eigenes Mobilgerät inkl. Halterung (nicht im Lieferumfang des Streuers enthalten) und die kostenlose LEHNER LISA App. Unsere LISA-fähige LEHNER-Streuer sind eigene, geschlossene System-Lösungen, weshalb ein Um-/Nachrüsten von bestehenden LEHNER-Streuern mit Bedienteil auf eine App-Lösung nicht möglich ist.

Der feine Unterschied

Schieber und Streuteller sind aus rostfreiem Edelstahl gefertigt (Edelstahlrahmen gegen Aufpreis). Das Rührwerk kann mit einem im Lieferumfang enthaltenen Rührfinger speziell für Gras-Aussaaten umgerüstet werden.

Flexibel & robust im Einsatz

Dank der 12 V-Technik und des umfangreichen Halterungsprogramms kann der SuperVario® mit nahezu allen Fahrzeugen betrieben werden, die in der Landwirtschaft zum Einsatz kommen – z. B. mit ATV, Pick-up etc.

OPTIONAL: AUTO-DOSIS

Bequem und komfortabel streuen – das Bedienteil LAS 4 mit Leermelder:

Mit der AUTO-DOSIS wird die Schieberstellung automatisch der gefahrenen Geschwindigkeit angepasst. Nach der Auswahl des Streuguts, Eingabe der gewünschten Streubreite und Ausbringmenge je Hektar reagiert AUTO-DOSIS automatisch auf Brems- und Beschleunigungsmanöver und regelt den Dosierschieber automatisch nach. Die gewünschte Ausbringmenge kg/ha bleibt immer konstant. AUTO-DOSIS zum geschwindigkeitsabhängigen Dosieren kann über zwei Möglichkeiten mit entsprechendem Zubehör realisiert werden.

1. AUTO-DOSIS über 7-polige Signalsteckdose

Hierbei wird die gefahrene Geschwindigkeit über die 7-polige Signalsteckdose am Traktor abgenommen. Zusätzlich enthält diese Variante den Vorgewendemanager über die Signalsteckdose.

2. AUTO-DOSIS über GPS-Empfänger

Die Geschwindigkeit wird über GPS ermittelt und an das Bedienteil weiter gegeben.

Downloads

Prospekt

SuperVario®

2 MB

Zubehör

Y-Verteiler-Kabel

Vorgewendemanager über 7‑polige Steckdose

Vorgewendemanager mit Sensor und Magnet

Halterungen

Pick-Up-Halterung verstellbar

Dreipunktbock KAT 0, KAT I, KAT II